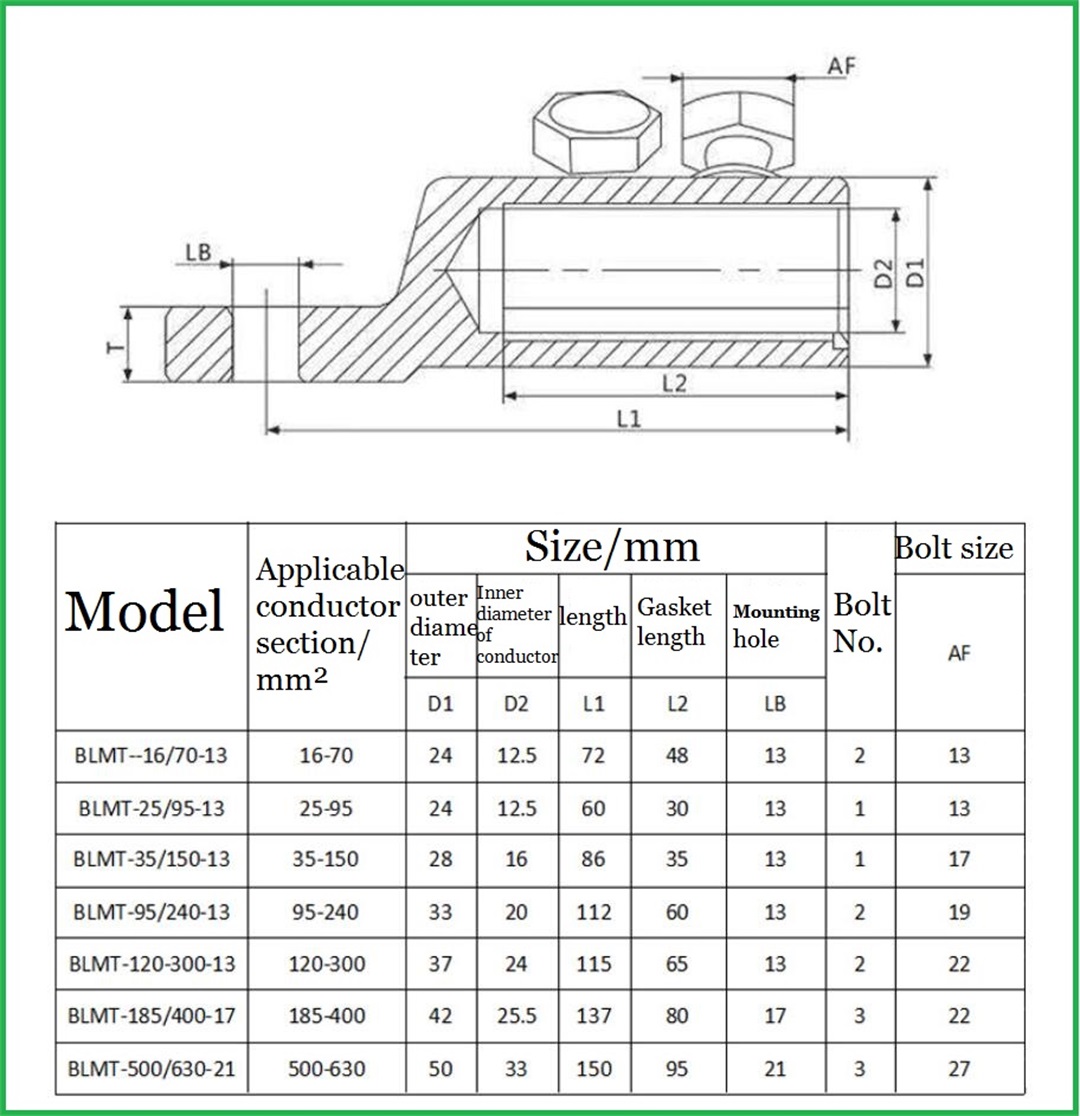

AML(BLMT) 16-630mm² 35KV and below Aluminum alloy torque terminal lug for conductor and equipment connection

Product Description

AML (BLMT) series alloy torsion terminals are wire and equipment connection type power fittings, mainly used in insulated wires, aluminum stranded wires, aluminum alloy stranded wires, steel cored aluminum stranded wires and pole-mounted circuit breakers, isolating switches, fuses, lightning arresters As well as power transmission and distribution equipment such as molded case circuit breakers, for connection at non-load-bearing positions.

The torque terminal is the torque terminal, which is to connect or terminate the cables by means of torque construction nails, including the torque terminal and the torque connection tube.

Torsion terminal BLMT is a high-strength special aluminum alloy material (6061), which is a crimp-free screw terminal made of an integral forging process.

Product features

(1) Bolt-type torque terminals are suitable for the connection between wires and flat electrical equipment in distribution lines of 10kV and below, and the connection method is mechanical connection without crimping.

(2) Bolt-type torque terminals are suitable for wires of various specifications , free from tedious selection and inventory control.

(3) The bolt-type torque terminal adopts a mechanical connection design, which avoids the use of special installation tools for crimping, and is easy and reliable to operate, reducing the risk of uncontrollable man-made during installation.

Product structure requirements and installation instructions

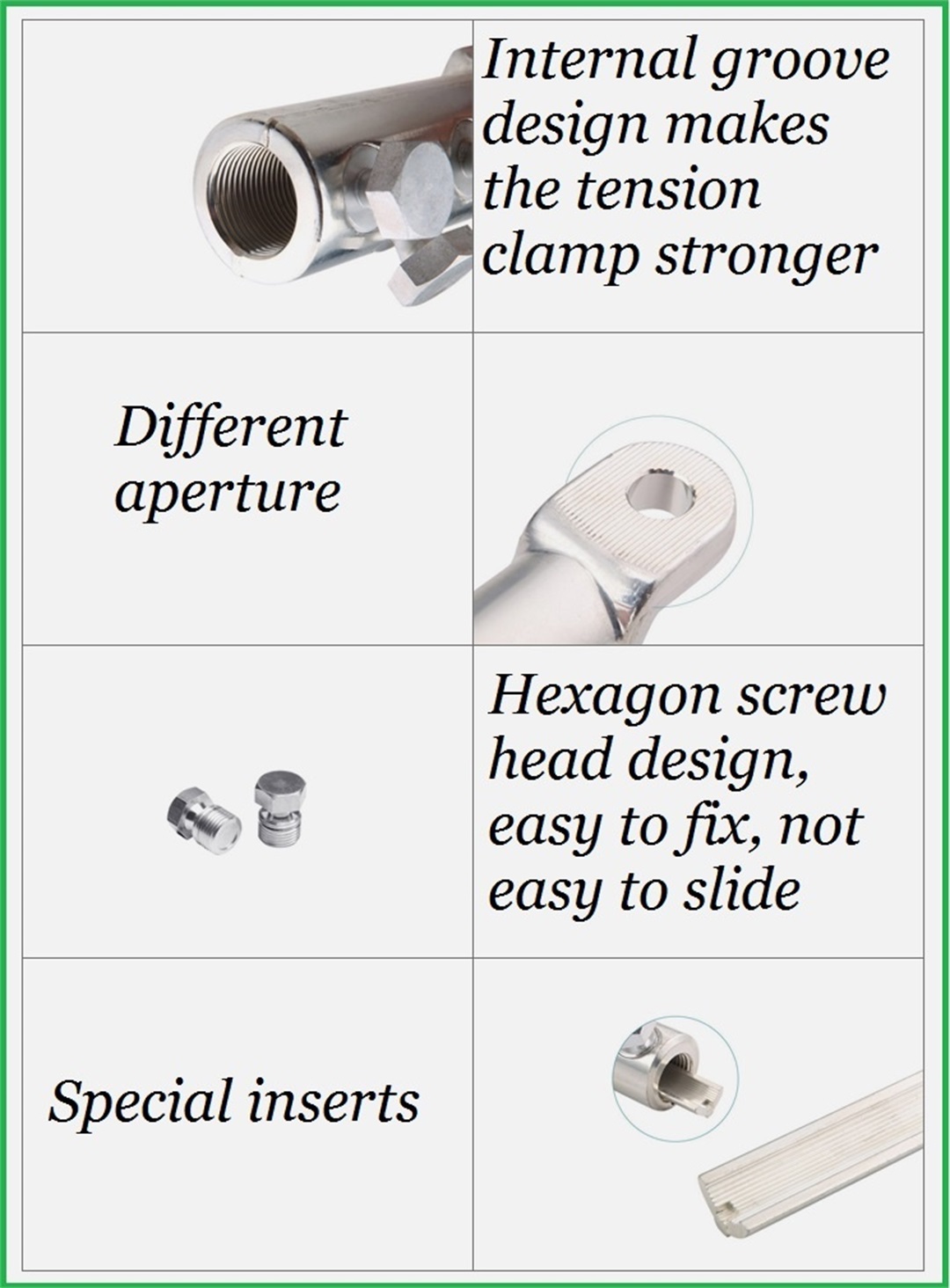

1. The body of the bolt-type torque terminal should be made of high-strength aluminum alloy, and then processed by a special process (tin plating) to meet the connection between conductors of different materials, and can be used without complicated assembly, and can be connected to copper cables/aluminum cables /Aluminum alloy cable.

2. The body is made of alloy material, which should have excellent metal elasticity, and can eliminate the stress caused by the thermal expansion and contraction of the wire and the device. The contact area between the device and the wire should be maximized to ensure that the wire and the device are in an optimal connection state, preventing the wire from creeping and ensuring that it will not loosen during operation.

3. Bolt-type torque terminals and torque equipment clamps adopt mechanical connection bolts, and shear nuts should be made of alloy materials with high-strength electrical conductivity and strong current-passing capacity. After special processing, oxidation and electrochemical corrosion are slowed down.

4. When the force of the universal wrench on the upper hexagon of the mechanical bolt meets the requirements, the mechanical bolt should be cut off when it reaches the preset installation torque, and the upper hexagon nut should break, indicating that the installation is complete, and the bolt section should not protrude The body has no burrs. The crimping force of the bolt to the wire is constant and sufficient to securely crimp the wire.

Product details

Products real shot

A corner of the production workshop

Product packaging

Product application case