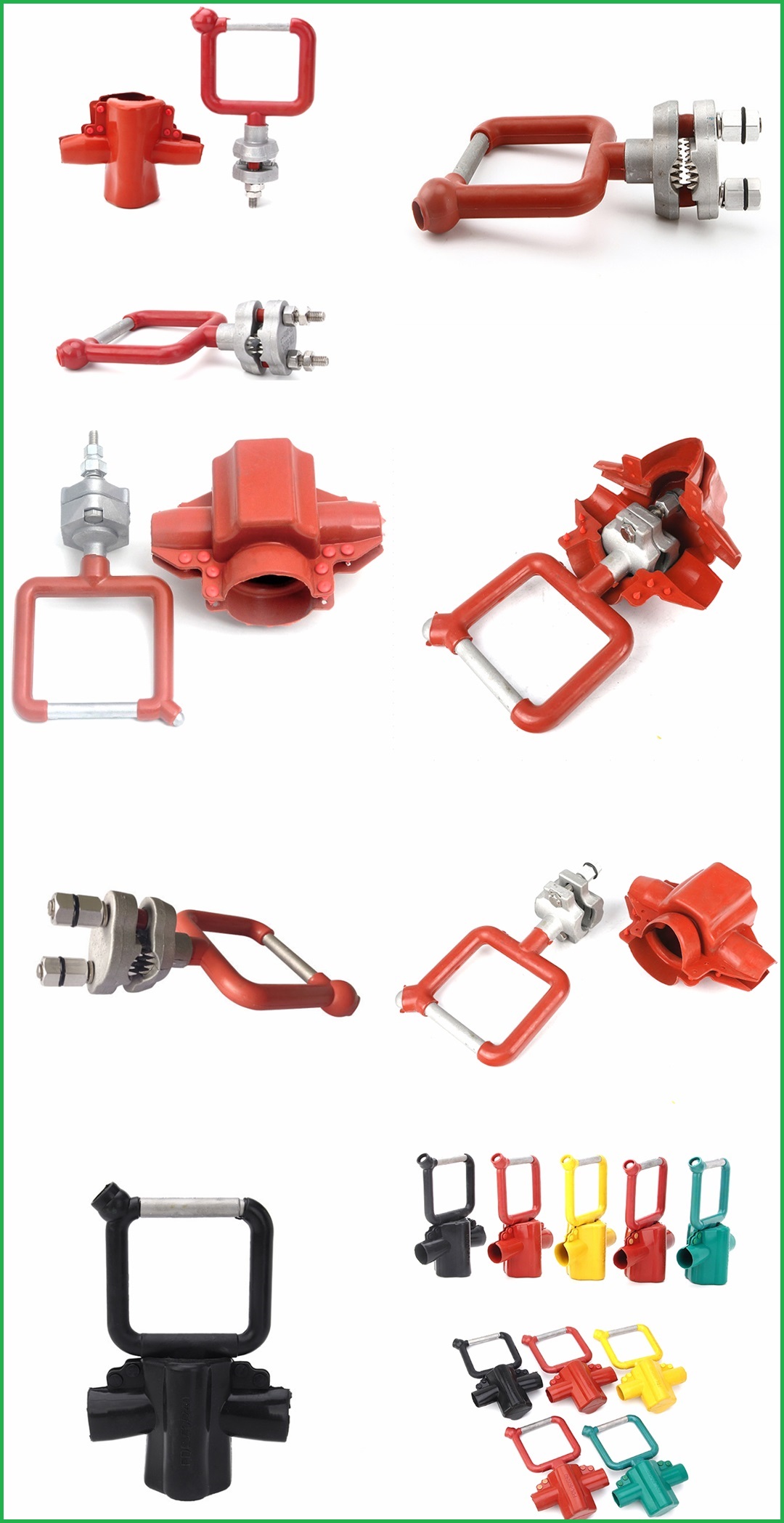

FHJDC 10KV Overhead Wire Lightning Protection Ground Clamp

Product Description

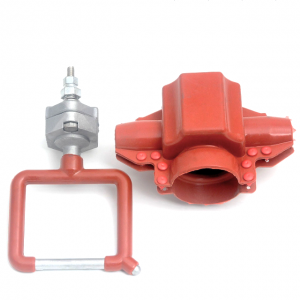

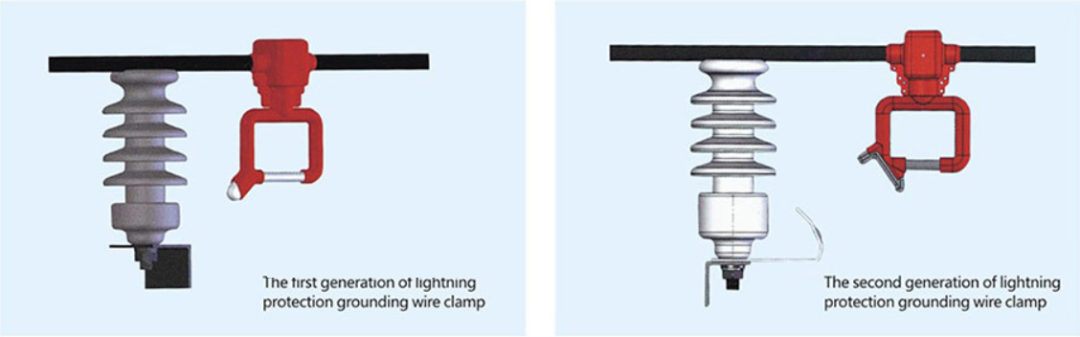

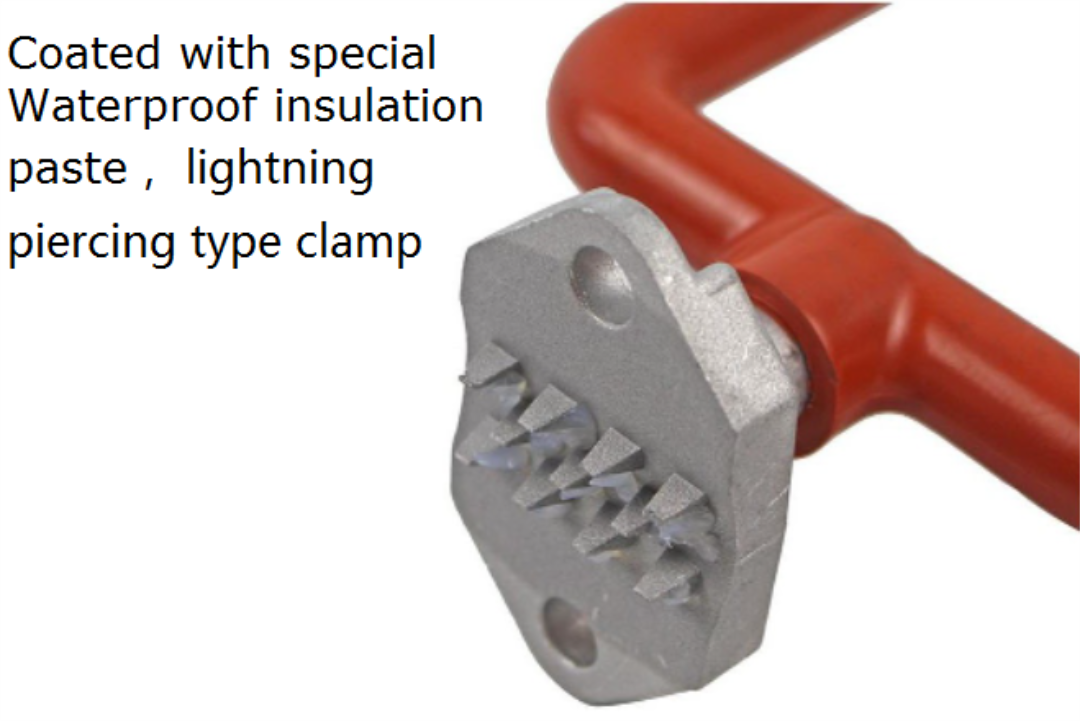

The lightning protection grounding clip developed by our company adopts a unique piercing tooth structure and electrode design, which is easy to install (no need to strip off the insulating layer), and has the characteristics of reliable performance. The second-generation products have better arc extinguishing performance and have great promotion value. .

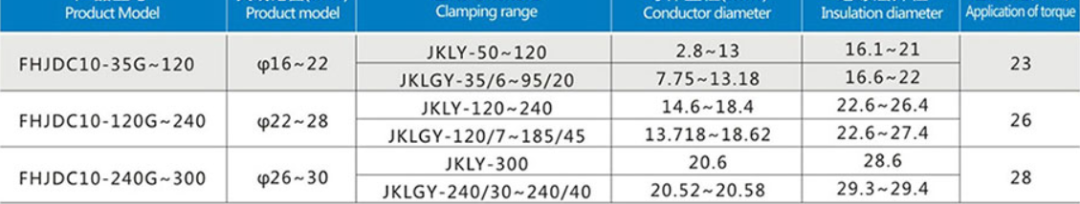

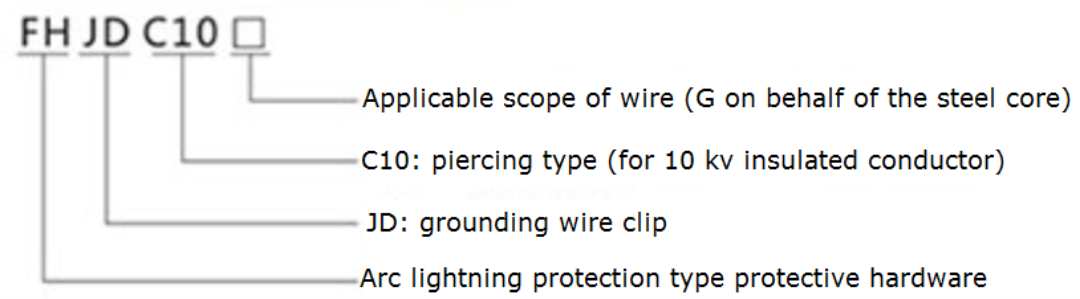

Model Description

Product features and installation method

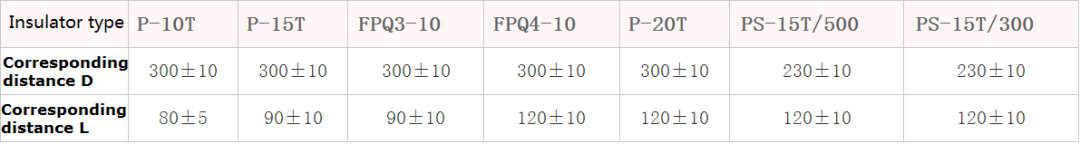

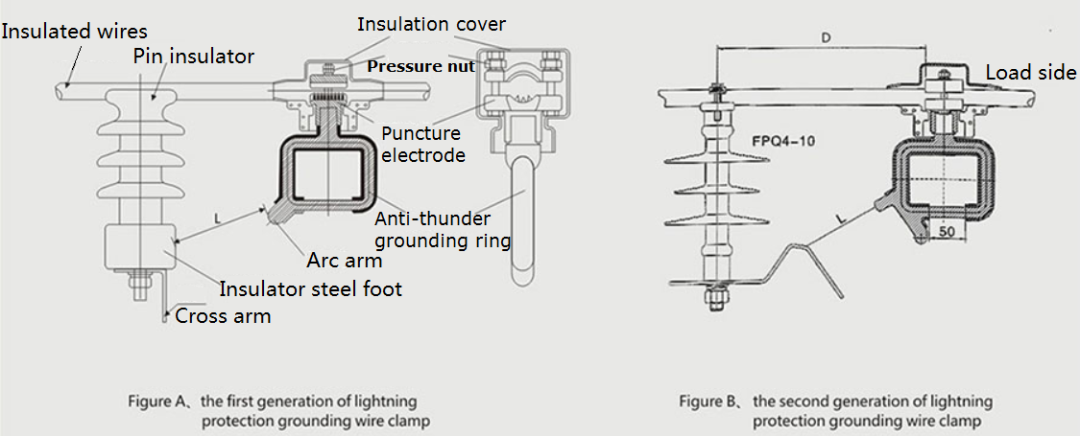

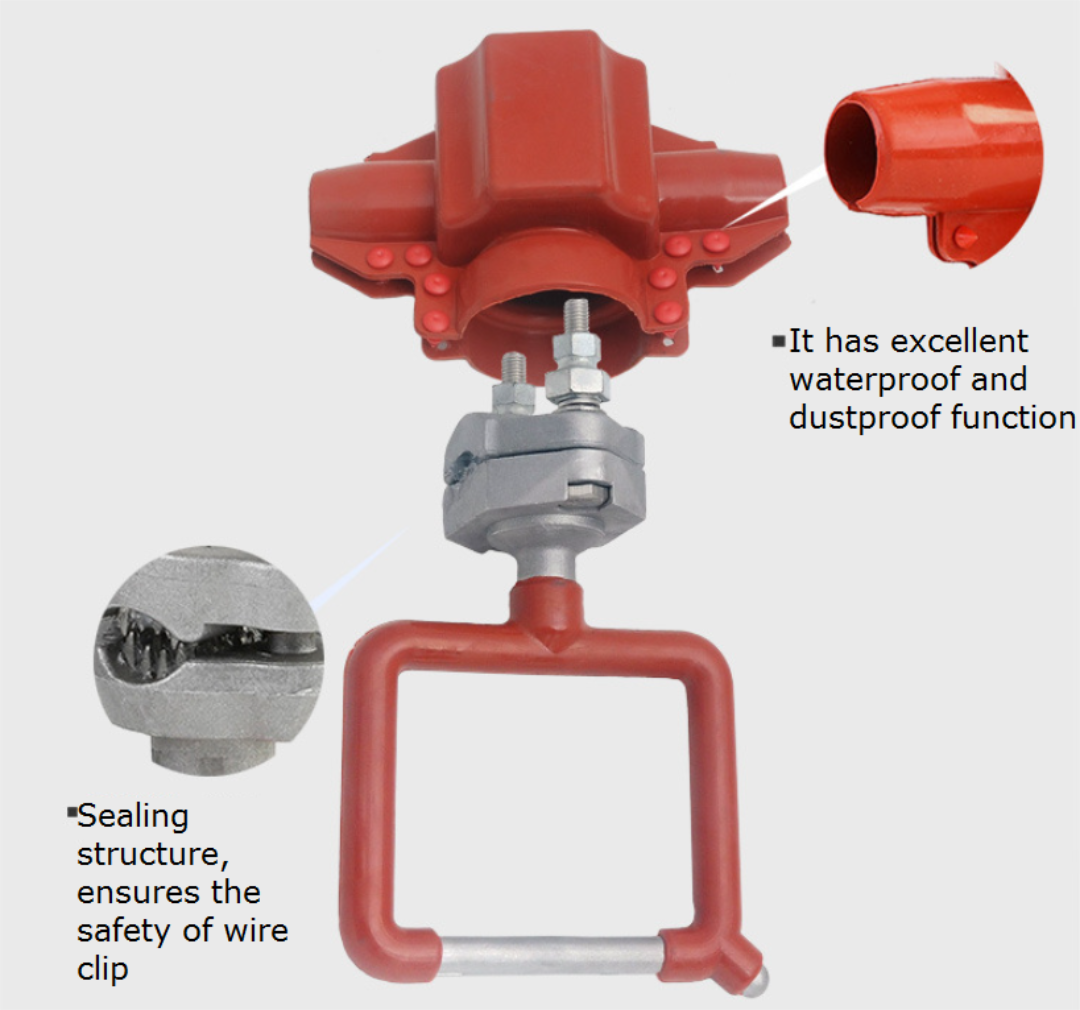

The overhead insulated wire lightning proof grounding wire clip has the structure of ordinary grounding wire clip, and adds the outer gap discharge device, The puncture electrode on the upper end can penetrate the insulation layer of the wire make the lightning protection grounding ring form an electrical connection with the wire, Hang ground rod in line maintenance as the grounding line connection; An arc-striking electrode is arranged at the outer lower corner of the lower end of the grounding ring. The discharge gap is formed corresponding to the steel foot flange of the line column insulator PS15 or P20, (If matched with composite insulators or other insulators, special grounding electrodes should be installed). During normal operation, there is a large air gap between the arc-striking electrode and the insulator steel foot flange or the grounding electrode, and no current flows. A flashover is caused between the arc electrode and the ground electrode (or the steel foot flange of the insulator), forming a short-circuit channel, and the continuous power frequency arc will be between the arc electrode of the lightning protection grounding clamp and the ground electrode or the steel foot flange of the insulator. It burns and releases overvoltage energy to protect the wire from being burned and disconnected.

I developed the company to adopt unique puncture tooth structure and electrode design, easy installation, without stripping the insulation, the characteristics of reliable performance, the second generation product arcing performance better, have a great promotion value.

1. The wire clamp groove of lightning protection pillar insulator should be installed on the cross arm parallel to the conductor, and the steel foot nut should be secured, which is equivalent to the traditional installation method of insulator, and the arc leading rod should be directed towards the far side of the cross arm (the furthest distance from the cross arm); The arc starting rod should be oriented in one direction, preferably towards the load side;

2. There are two methods of perforation and clamping: (1) Tightening method of the torque nut: insert the insulated wire into the slot as parallel as possible, first tighten the torque nut by hand, and then use a socket wrench to alternately and evenly tighten until the torque The top of the nut comes off. (2) According to the cross section of the wire and the weather temperature, set the torque wrench value to 20-35Nm, and use the torque wrench to tighten the two pressure nuts alternately and symmetrically. The root is enough, and then tighten the backup nut to prevent the pressure nut from loosening;

3. The non-piercing method of wire clipping is: strip off a section of insulated wire of about 65-80mm, wrap it with aluminum clad tape and embed it on the insulator wire clipping hardware. Tighten the compression nut with a wrench to drive the compression block to compress the wire, so as to assemble the insulating sheath to the outside of the compression metal fixture. (For details, please refer to the product installation manual)

Product details

Products real shot

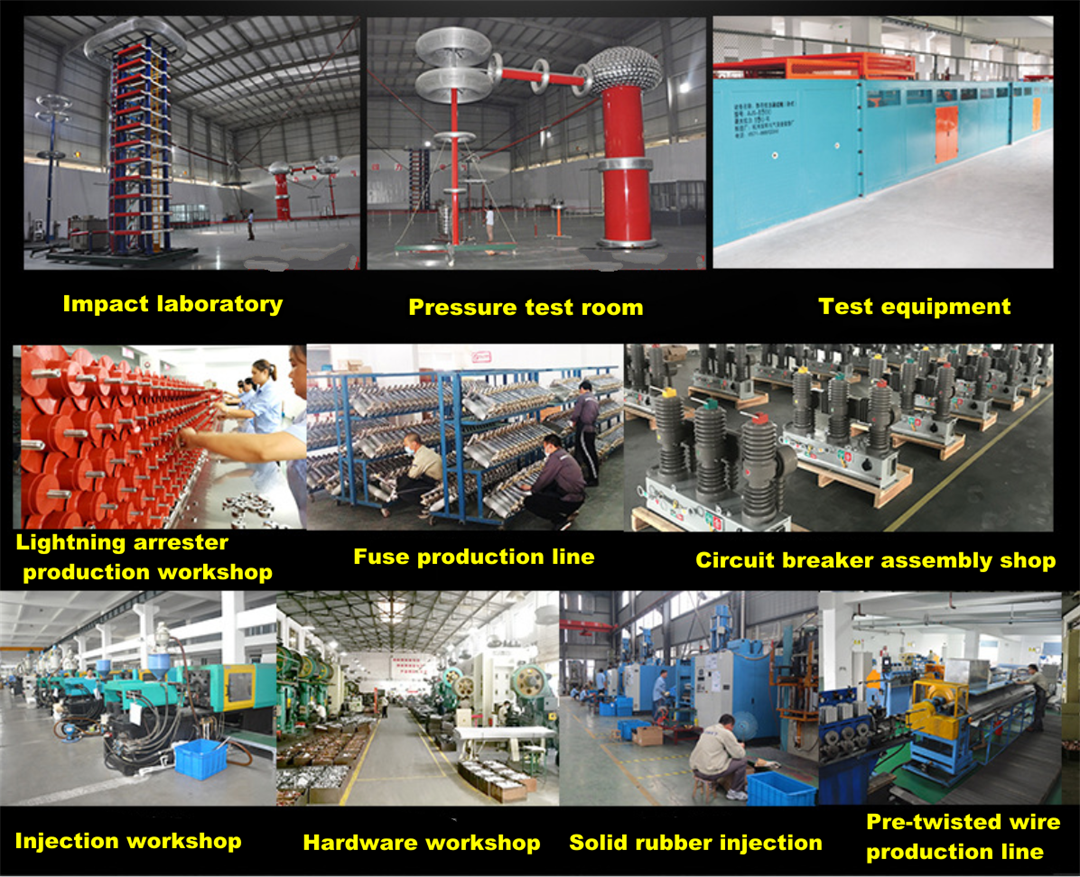

A corner of the production workshop

Product packaging

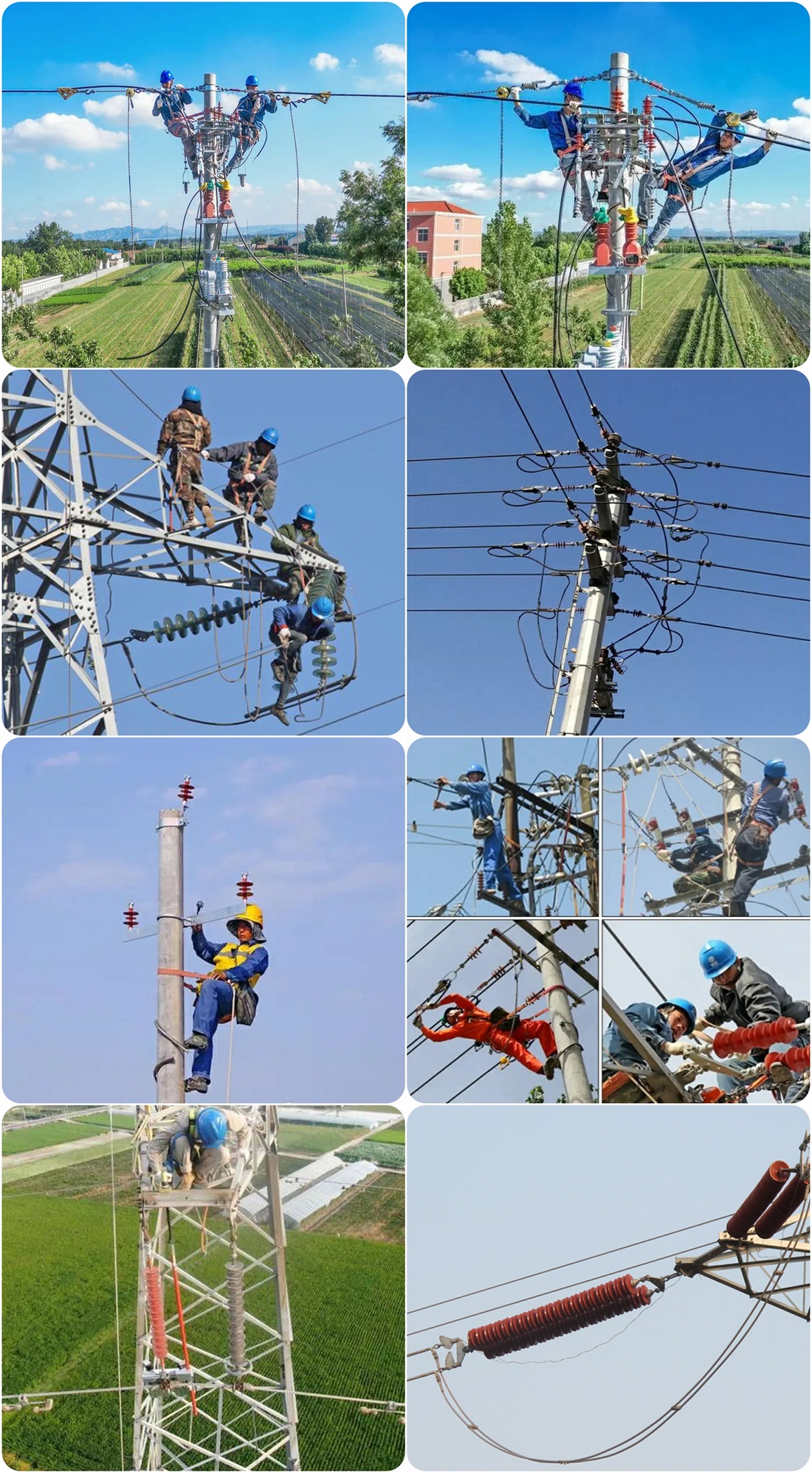

Product application case