SBW 25-300mm² Electric Power Equipment clamp Transformer&disconnector Aluminum alloy torque locking connection device

Product Description

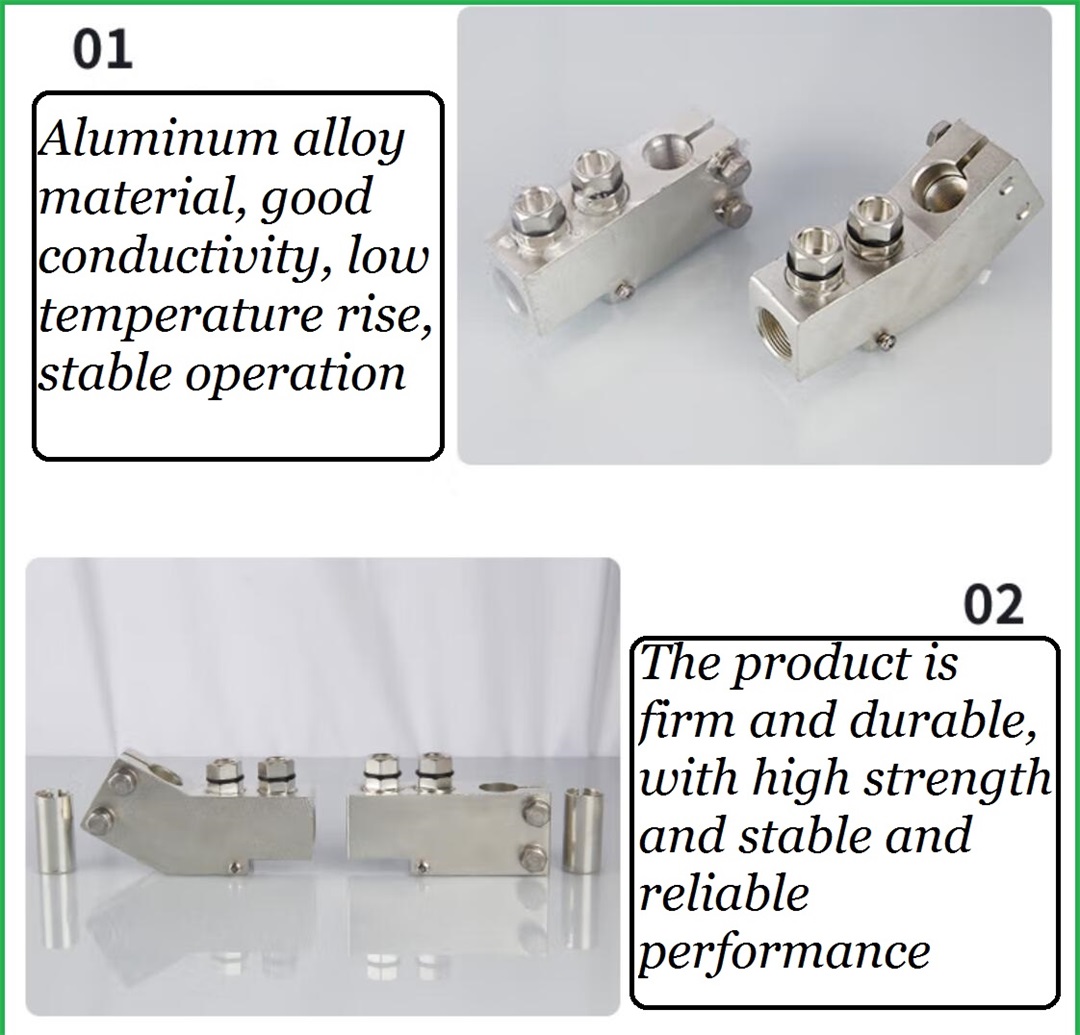

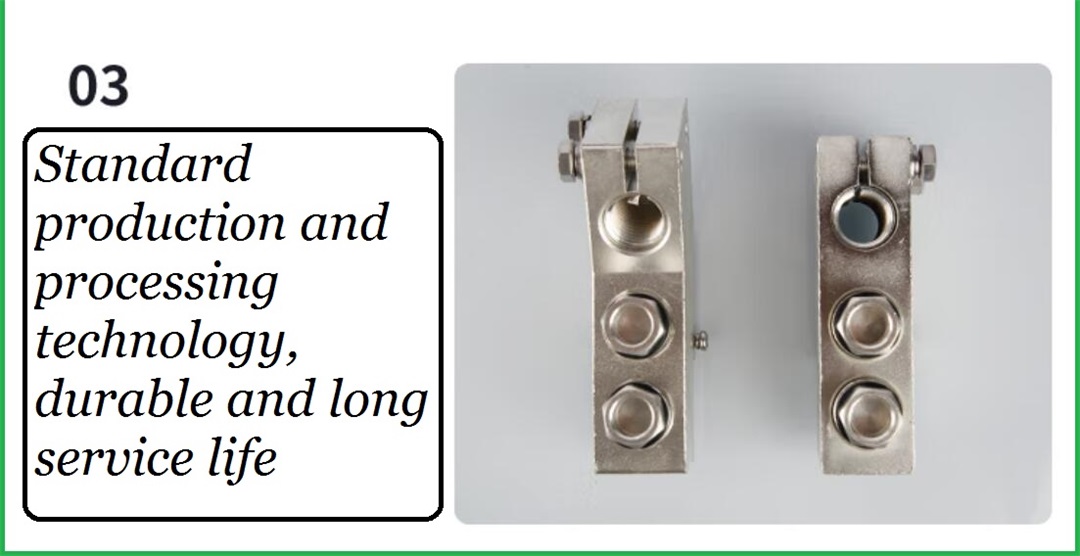

Torque locking connection device, the body is made of high-strength aluminum alloy material, and it is processed by special technology after forming, so it can be used without complicated assembly. The body is made of aluminum alloy with excellent metal elasticity, which can eliminate the stress caused by thermal expansion and contraction of wires and devices. The contact area between the device and the wire should be maximized to ensure the best connection between the wire and the device, prevent the wire from shaking, and ensure that it does not loosen during operation. The torque lock connection device has the characteristics of strong versatility and convenient selection. Torque locking clamp device B is applied to the connection device (torque locking clamp device A)

between switchgear (such as: isolating switch, fuse, lightning arrester, load switch, etc. ) SBW series transformer clamp is a new type

Special clamps for transformers. One end of the clamp body is a wire installation screw hole, and the other end is a pole-type threaded hole connected to a transformer, which can meet the connection with transformers of different capacities (30-400KVA). It is made of special alloy with high strength, high conductivity and intermediate electrode potential through special process. The connection is stable and reliable, and has good mechanical and electrical properties. It can effectively solve the problem of large contact resistance and serious heating when connecting the incoming and outgoing lines of distribution transformers. , connection failure and other issues

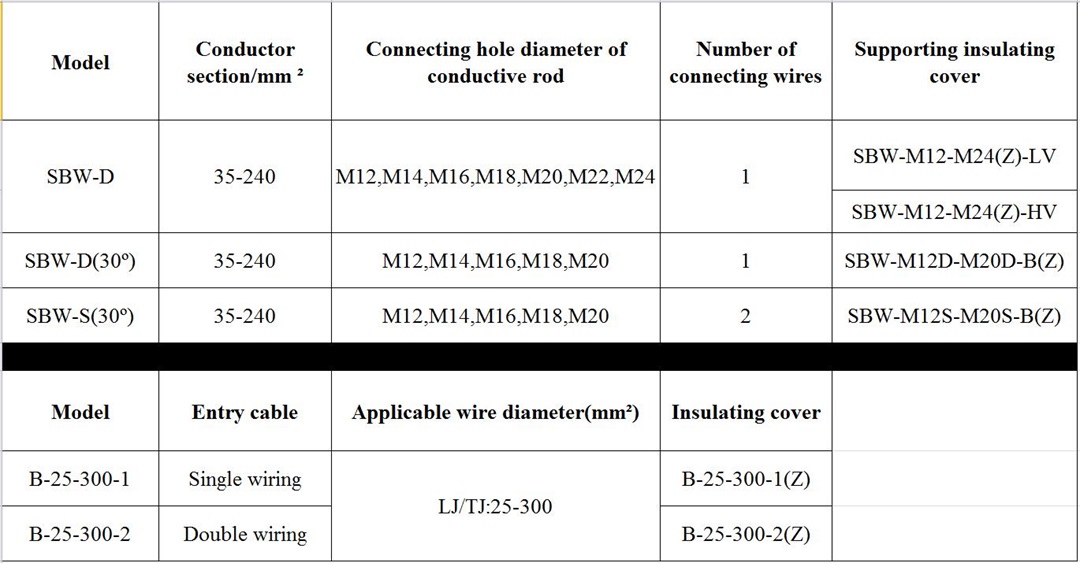

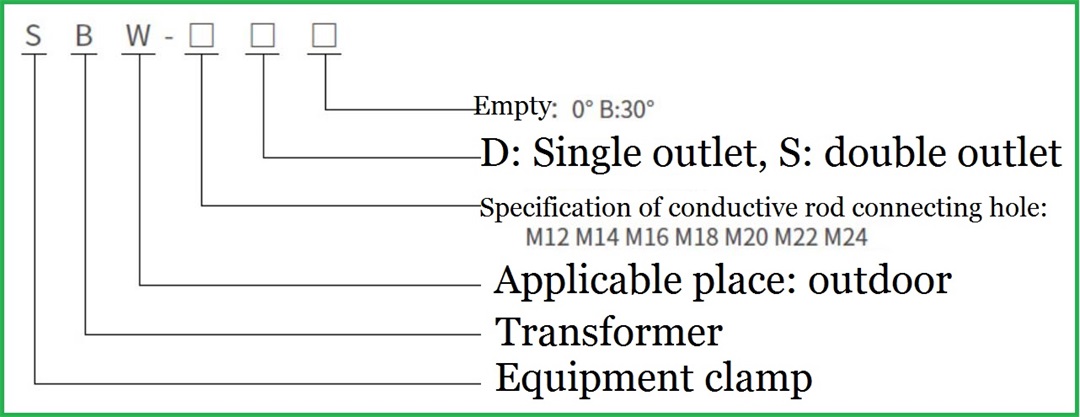

Model description

Product structure characteristics and use environment

Structural features:

1. Wide application range: suitable for transformer wiring connection with a capacity of 30-400KVA and various specifications;

2. Strong versatility: suitable for wire connection with a cross-sectional area of 35-240mm², eliminating the trouble of type selection;

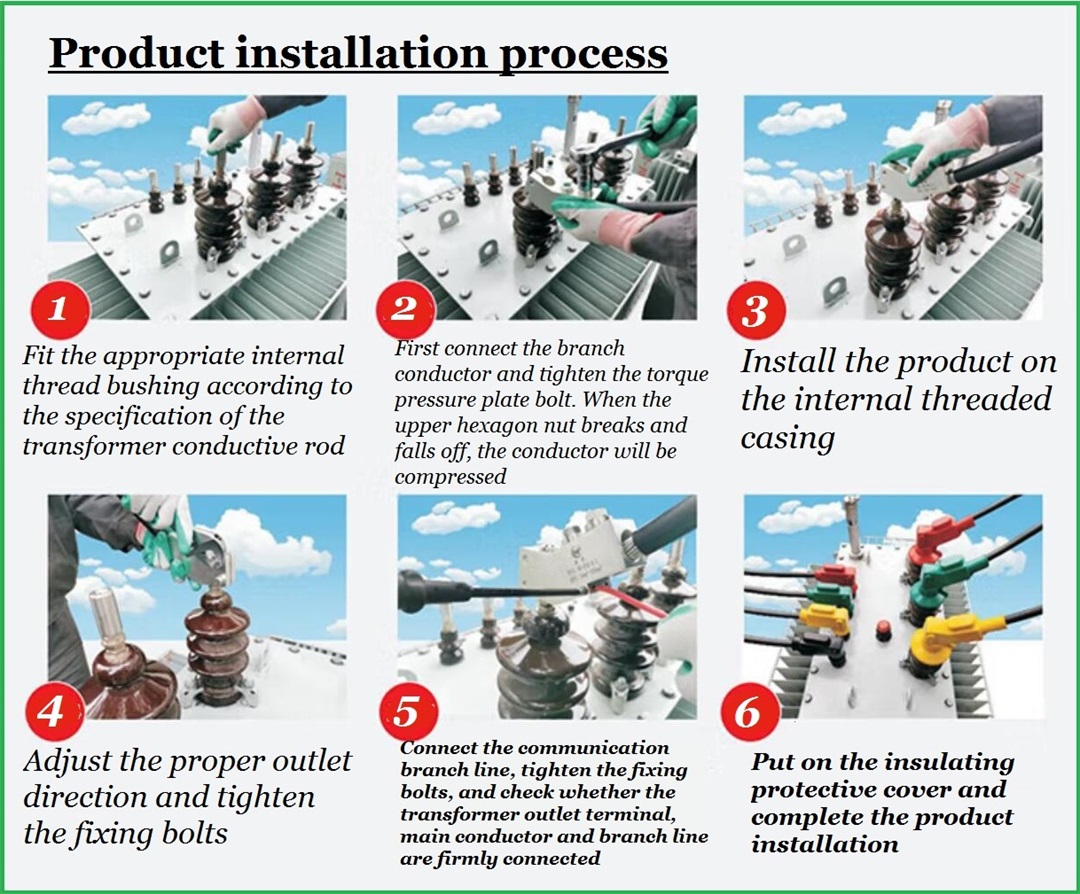

3. Easy installation: the torque self-locking pressure plate bolts are directly crimped without damaging the wire, and no special tools are required;

4. Elastic design: the incompletely closed inner threaded casing can effectively prevent creep;

5. Corrosion and oxidation resistance: heat treatment process and tin plating on the surface

6. Energy saving and low consumption: Large wire contact area and strong flow capacity; 7. Insulation protective cover: made of aging

-resistant and flame-retardant silicone rubber, waterproof and electric shock-proof, and keeps the line insulated.

Applicable environmental conditions:

1. Altitude: ≤ 3000m;

2. Maximum ambient temperature: +50oC, minimum ambient temperature: -40oC;

3. Annual average temperature: 20oC;

4. Maximum daily temperature difference: 30oC;

5. Sunlight intensity: 0.1W/cm2( Wind speed 0.5m/s, 0.6m/s for large span);

6. Ice thickness: 0 ~ 50mm;

7. Maximum wind speed: 35m/s (once in 30 years at a height of 10m above the ground, 10-minute average maximum value) ;

8. Relative humidity of the environment: daily average: 95%; monthly average: 90%;

9. Pollution level: 0 ~ Ⅳ level;

Product details

Products real shot

A corner of the production workshop

Product packaging

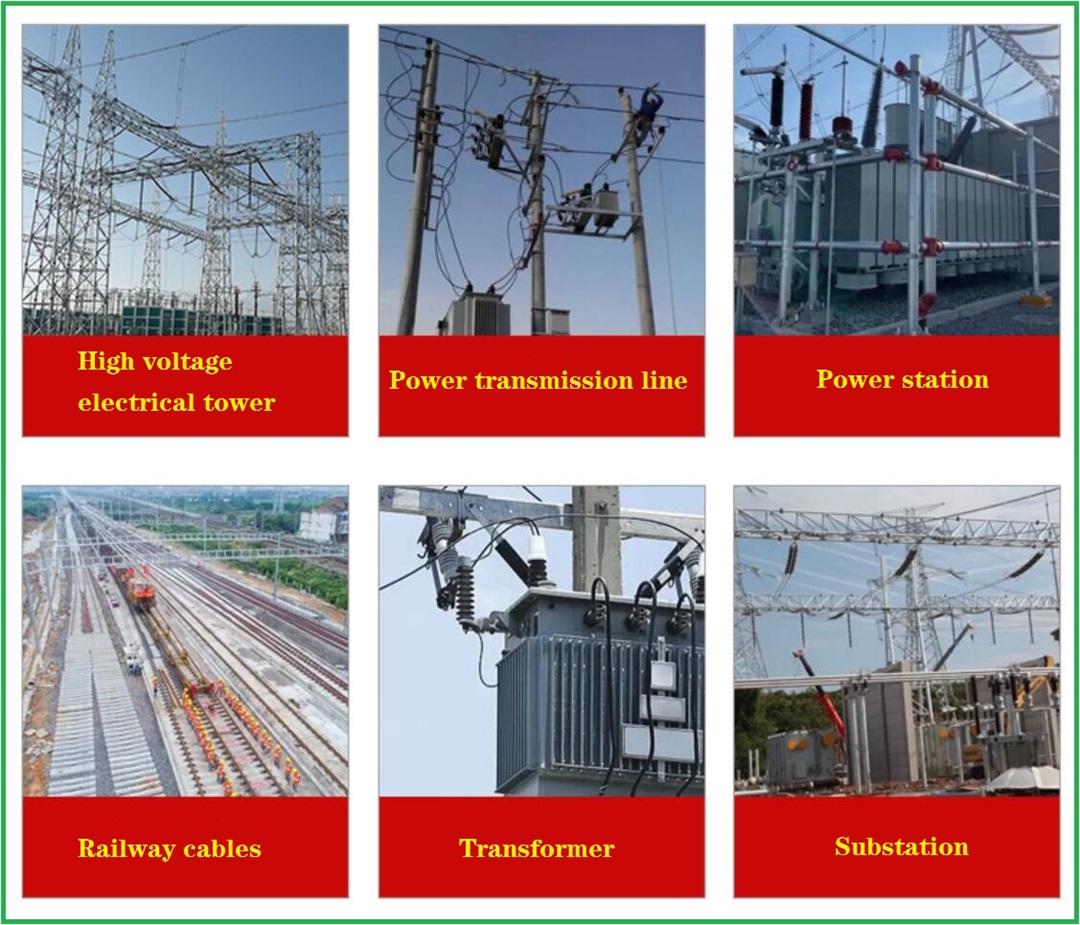

Product application case