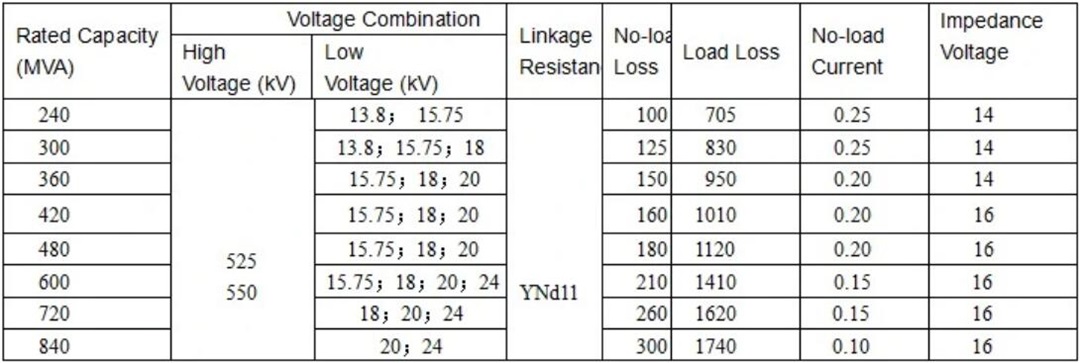

S(F)S(Z) series 220/330/500KV 31500-300000KVA Intelligent three-phase ultra-high voltage oil immersed on load voltage regulating power transformer

Product Description

Our Factory produce voltage rating 500kV and below, capacity rating 1000MVA and below series oil immersed power transformers. Through optimization and innovation, we have successfully produced a series of power transformers with low noise, low loss, low partial discharge and high short-circuit resistance. The power transformer has adopted a series of major reforms in materials, processes and structures, featuring small size, light weight, high efficiency, low loss, low noise and reliable operation, which can reduce a large number of power grid losses and operating costs and achieve remarkable economic benefits. Applicable to power plants, substations, large factories and mining enterprises, etc. This product complies with national standards: Power Transformers Part 1 General Rules (GB1094.1-2013), Power Transformers Part 2 Temperature Rise (GB1094.2-2013), Power Transformers Part 3 Insulation Levels, Insulation Tests and External Insulation Air Clearances (GB1094.3-2003), Power Transformers Part 5 Short Circuit Resistance (GB1094.5-2003)

220/330/500kV transformers are high voltage oil-immersed transformers with a heart structure. According to the number of phases can be divided into single-phase transformers, three-phase transformers; according to the regulating method can be divided into on-load regulating, non-excitation regulating; according to the winding coupling method can be divided into power transformers, autotransformers; according to the number of windings can be divided into double-winding, three-winding, three-winding + balance winding. Also included are split transformers, combined transformers and other special types of 220/330/500kV transformers. The products are designed according to IEC international standards, IEEE standards and current national standards.

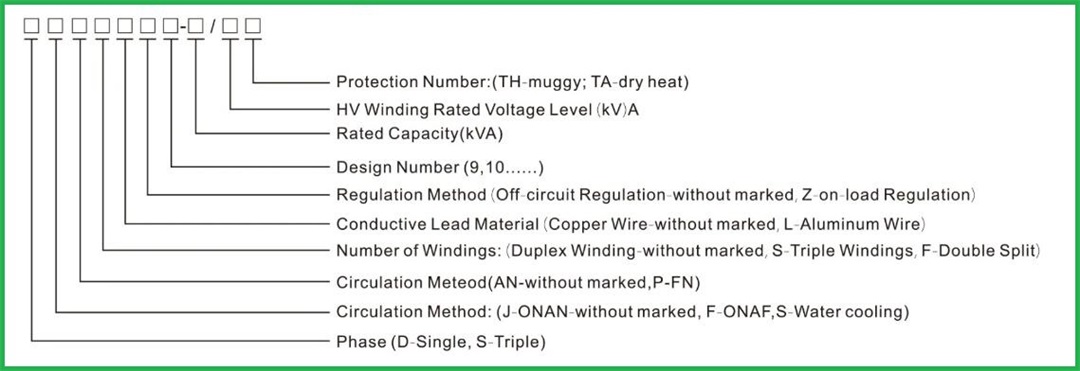

Model Description

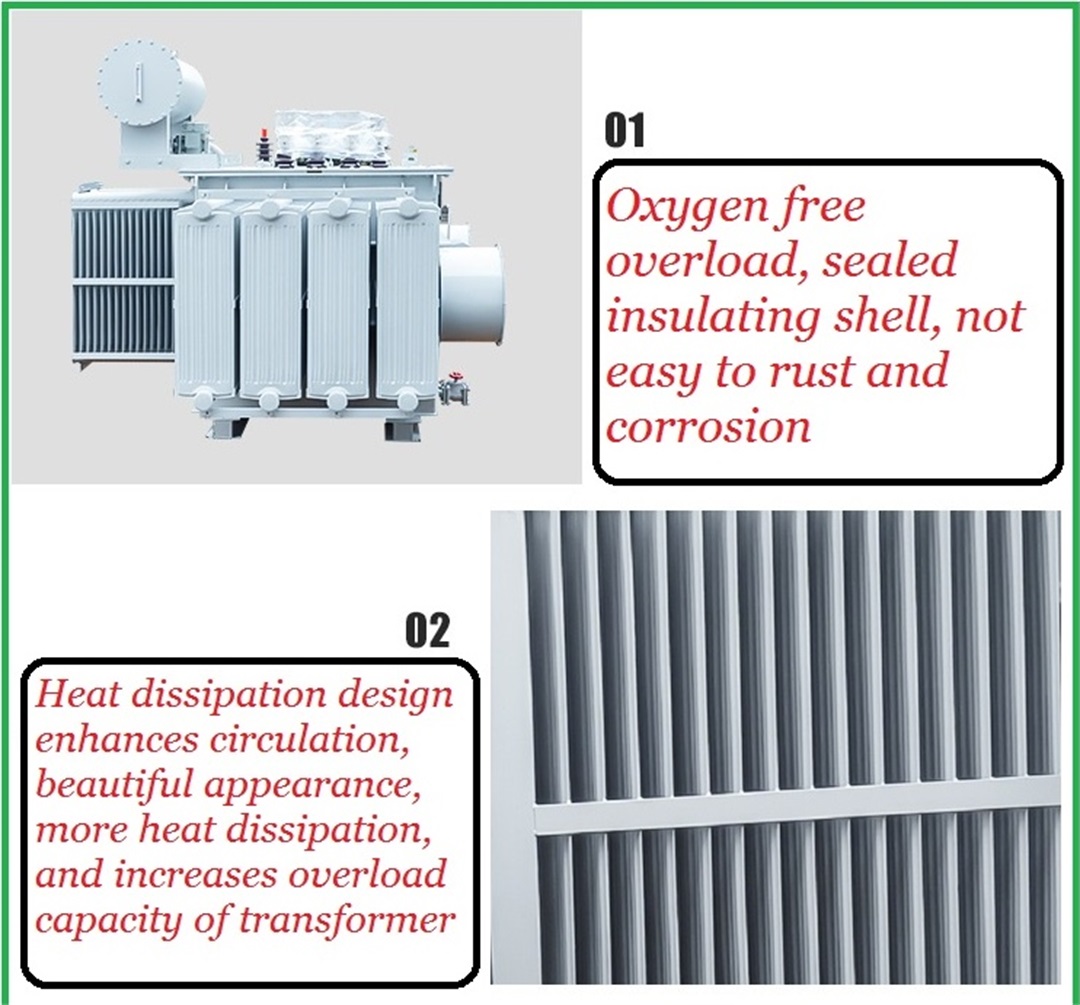

Product features and advantage

Product superiority:

1.Low no-load loss, low no-load current, low noise

The Laminated core type transformer Adopt multistage step lapped joint fully-oblique structure, can reducing magnetic resistance and noise; Its cross section is inscribed polygon, high fill factor. After high temperature annealing of eliminating stress, no-load loss is greatly reduced.

2.Strong overload capacity

With oil flow guide control technology, the quantitative calculation of the oil flow, optimize the structure of oil circuit, reduce the hot-spot coefficient, to ensure that under the condition of rigorous overloading load, the winding hot-spot temperature does not exceed 140 ºC.

3.Strong anti-short circuit ability

By analyzing and calculating the worst short circuit, adopting high strength wire and effective support to strengthen the structure, adjusting the coil distribution to ensure all stress have enough margin. Self-developed winding technology can make the coils wind tightly.

4.Low partial discharge

Strictly control each part of the electric field intensity, according to the discharge requirements, coil winding and internal assembly is in the dustproof workshop to guarantee the body clean, adopts the high vacuum oil injection process, effectively control discharge of product.

Structure characteristic:

1,Iron core

1. 1The iron core adopts cold-rolled crystal-oriented silicon steel plate 30Z140 with high quality, low-loss, and no

time effect, sheared by Geroge line and with no burr. 1.2 Iron core adopts pulling board structure, the upper

and down yoke is clamped by board, to form the frame structure. The iron core adopts advanced lamination

process, which effectively controls the no-load loss and electro-magnetic noise.

2 Winding

2.1 Winding adopts mature structure, which ensure the reliability of transformer operation.

2.2 The insulation power field intensity between turns shall be controlled no greater than 1.6kV/mm.

3,Body

3.1 Body adopts mature insulation structure, and strictly guarantee the main axial insulation margin.

3.2 Body mostly adopt multi-coil whole assembly, processed in constant voltage and evaporation, which made

coil shrink evenly and with less rebounce, and enhance the electric strength and mechanical strength.

3.3 Adopt laminating wood board or thermal shaped insulation cardboard. Pressed tightly with pin, which ensure

the winding is constantly pressed tightly.

4,leading wire

4.1 The layout of all leading wire is reasonable, which guarantees the enough electric distance and mechanical

strenth.

4.2 All leading wire is cirlulized ,which guarantee the reliable wild or prize connection.

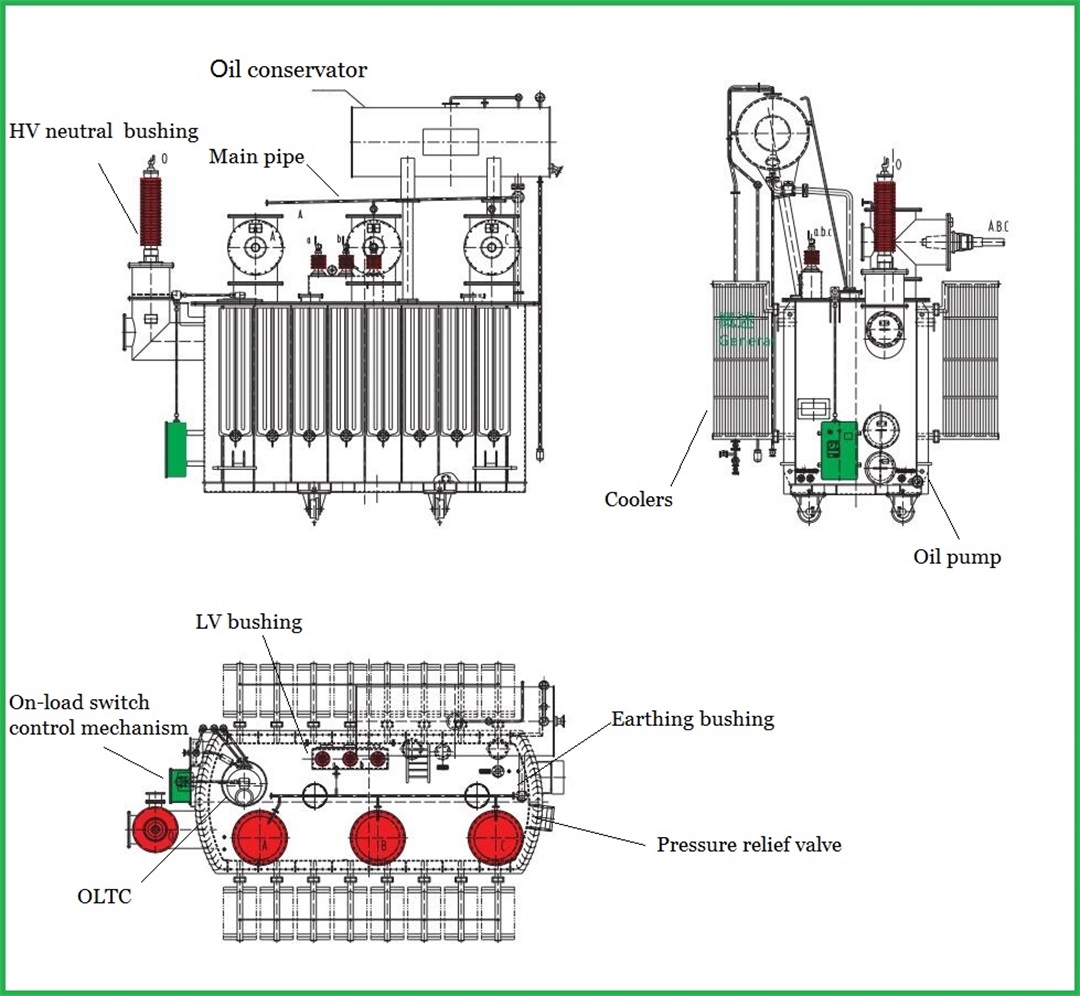

5,Oil tank

5.1 Oil tank adopts structure of flat top, bell jar type, which add the mechanical strength of oil tank and also

make the appearance beautiful and graceful, site installation tend to be more convenient.

5.2 Pipeline with gas relay such as the oil tube and bushing hoist support on top of oil tank is with hoist

gradient, to facilitate the gas in transformer flow to gas relay.

5.3 Vacuum oiling is adopted, there is no leakage and permanent distortion in the following test. vacuum-

pumping :759mmHg load voltage test: bear 2 times the oil pressure of oil conservator oil surface for 24 hours.

5.4 The structure of transformer is convenient for disassembly and change of bushing and porcelain element.

5.5 The oil drip valve is set on the bottom of oil tank, sampling valve is set in the middle.

5.6 collective gas connecting tube is fixed on the bushing hoist support.

5.7 Transformer is of full-sealed structure, the upper and down oil tanks are required to welded fully.

6,Oil conservation tank

6.1 Adopt capsule type, finger type oil level indicator oil conservation tank.

6.2 The structure is convenient for internal cleaning, the capacity can ensure no oil overflow in 40 ambient

temperature with full load, and oil shall be seen from oil level indicator before put into operation in -25.

6.3 Oil conservation tank is equipped with oil-sealed moisture absorber.

7,Safety protection device:

7.1 Gas relay is fixed in transformer, the standard complies with ZBK41004-89Gas relay.

7.2 There is enough and reliable pressure release device, and matched with oil spray pipe, the direction of oil spraying is downward.

8,Oil temperature measuring device:

8.1 There is pipe support of mercury thermometer, which is set on the top of oil tank.

8.2 There is temperature controller, the accuracy of thermometer complies with the related standard. Quantity and technical requirement shall as per tender document.

9,Each component of transformer shall be prefabricated once in manufacture factory, marked, to ensure the smooth procedure of site assembly. Before Ex-factory, inner core shall be check, and clean the fifth in transformer.

Product service conditions

1. Device type: outdoor

2. Environment temperature: -40ºC ~ +40ºC

3. Altitude: ≤1000 meters (>1000 meters, Needing modification on temperature rise)

4. Relative temperature: ≤ 90% (25ºC)

5. Installation place: No corrosive gas, pollution class: IV level and below.

Product details

Products real shot

A corner of the production workshop

Product packaging

Product application case