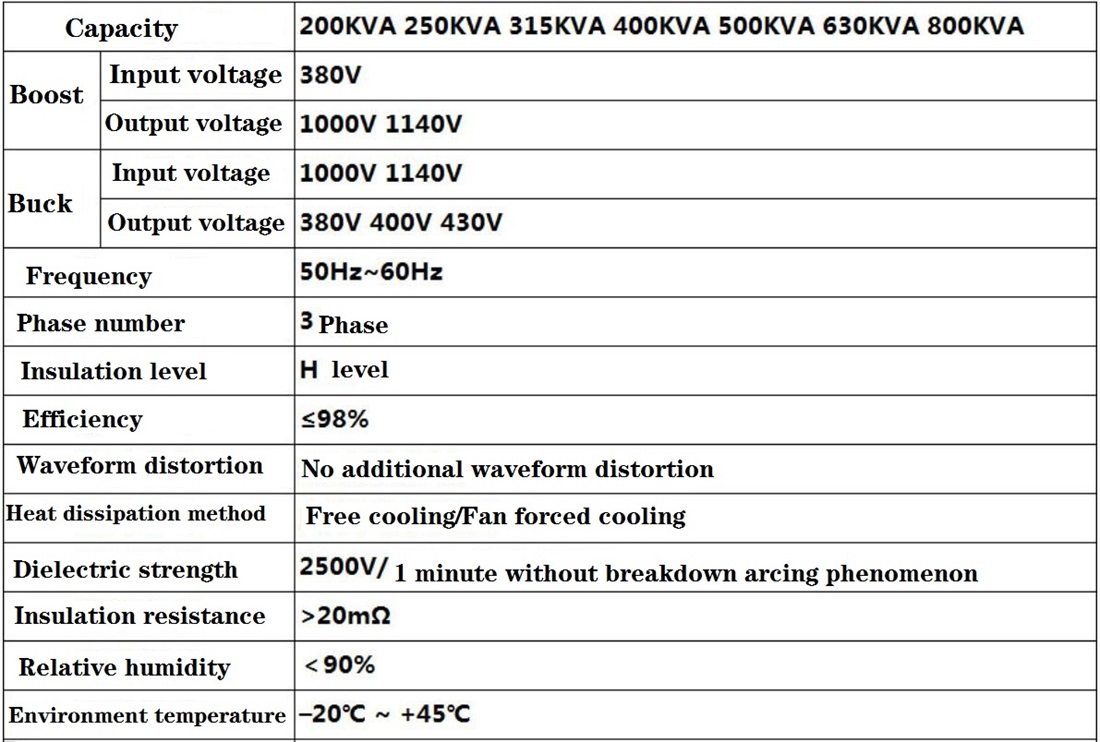

SG 100-3600KVA 380-3300V three-phase tunnel special booster dry-type transformer

Product Description

Tunnel construction step-up transformer (100KVA-2000KVA) This product can solve the problem that the voltage of the grid is 300v, or even the lowest, the voltage is too low due to the long line, and all the equipment cannot be started normally due to too many equipment. Rise to 380-450v, use electrical equipment to start and work normally. It is especially suitable for all kinds of electromechanical equipment such as crushers, ball mills, scrapers, conveyor belts, cement conveyors in remote mountainous areas, mines, tunnels and other places where the voltage is too low in factories, mines, highways, railways, tunnels, and irrigation. Pumps, air compressors, winches, mineral processing equipment or tunnel excavation equipment, shotcrete machines, tunnel boring machines, etc. Due to the long power supply distance and the large line loss, the voltage is reduced, so that all kinds of mining electromechanical equipment cannot be started normally, and even all kinds of mining electromechanical equipment can be burned. Tunnel mining machine automatic booster has the characteristics of wide boosting range and can automatically stabilize the power supply voltage (240V-430V) at (400V) output. Make all kinds of mining electromechanical equipment work normally at the end of the power supply. Other voltages are required, can be customized.

Product features and scope of use

Features:

1. It can solve the problem that the low-voltage grid voltage (300V-380V) equipment cannot operate normally due to the low voltage (less than 10KV) of the high-voltage grid during the peak period of electricity consumption.

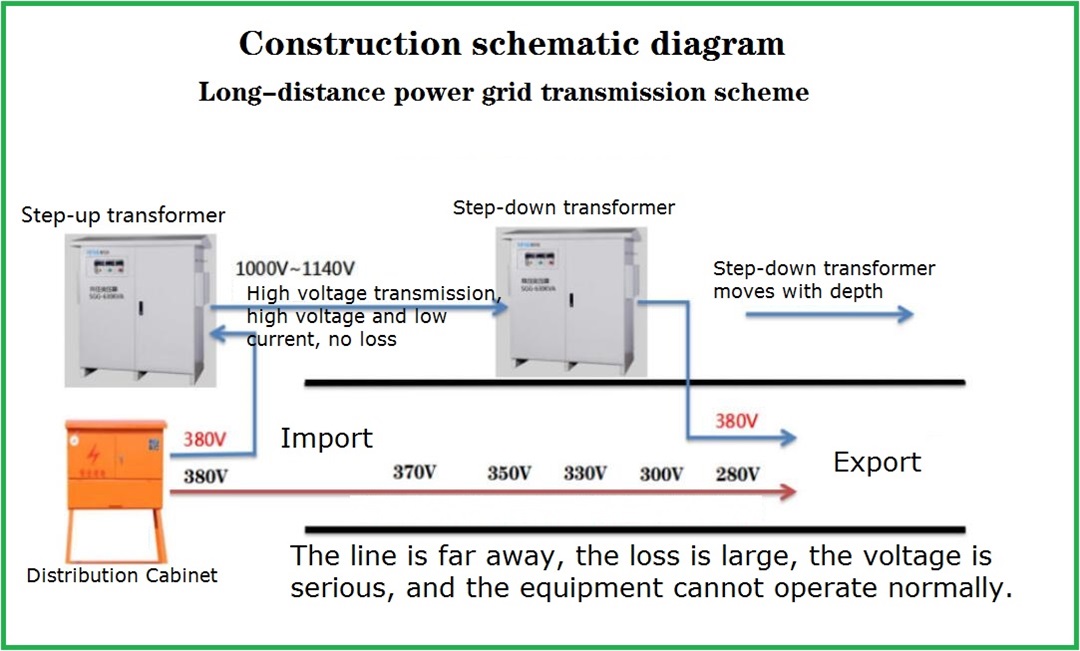

2. This product can solve the problem that the voltage of the high-voltage grid is normal, and the output of the transformer cannot reach more than 380V, but the equipment cannot operate normally because the low-voltage line is too long (within 2300 meters).

3. This product uses too many electrical equipment, resulting in a low voltage, which cannot meet the starting operation of all equipment.

4. This product can save about 40-50% of the cost compared with the generator generator.

5. The voltage stabilizer generally has higher requirements on the working environment, mainly because the integrated circuit of the device requires a better working environment and is easily damaged; the carbon brush brush speed is slow, and the instantaneous starting high voltage cannot meet the starting requirements; purchase The cost is high, the mission life is short, and the maintenance cost is high. This product can solve the instant high-voltage start, the purchase cost and maintenance cost are low, and the installation is simple and the use environment is not high, and the volume is small, which is convenient for mobile operations.

6. Some customers require that the transmission distance is relatively long, and combined equipment can be installed. A step-up transformer is installed at the head end of the line, and a step-down transformer is installed at the end of the line to meet the equipment startup and operation requirements.

7. It can operate continuously and reliably, with few faults, maintenance-free, etc.

8. It can solve the problem of too low voltage in 5000m-11000m tunnels, no need for high voltage to enter the hole.

Environmental conditions:

1. Ambient temperature: -20~85

2. Relative humidity: ≤90%;

3. The installation site should be free of gas, steam, chemical accumulation, dust, dirt and other explosive and corrosive media that seriously affect the insulation of the equipment;

4. The installation site should be free from severe vibration or stable;

5. In rainy weather, prevent lightning strikes, rain, fear of fire, and equipment should not be pressed or stepped on.

Ordering information

1. The user's voltage situation The user is required to detect the no-load voltage value and the load voltage value.

2. The distance between the transformer and the electrical equipment The user needs to measure the distance between the user's transformer and its electrical equipment.

3. The user's cable situation The user needs to check the situation of the cable used by himself. Generally, it is necessary to match the total power of the equipment.

4. The total power of the starting equipment The user should check the total power of the equipment used by himself.

According to the above information, the user can choose the corresponding model product or propose customization.

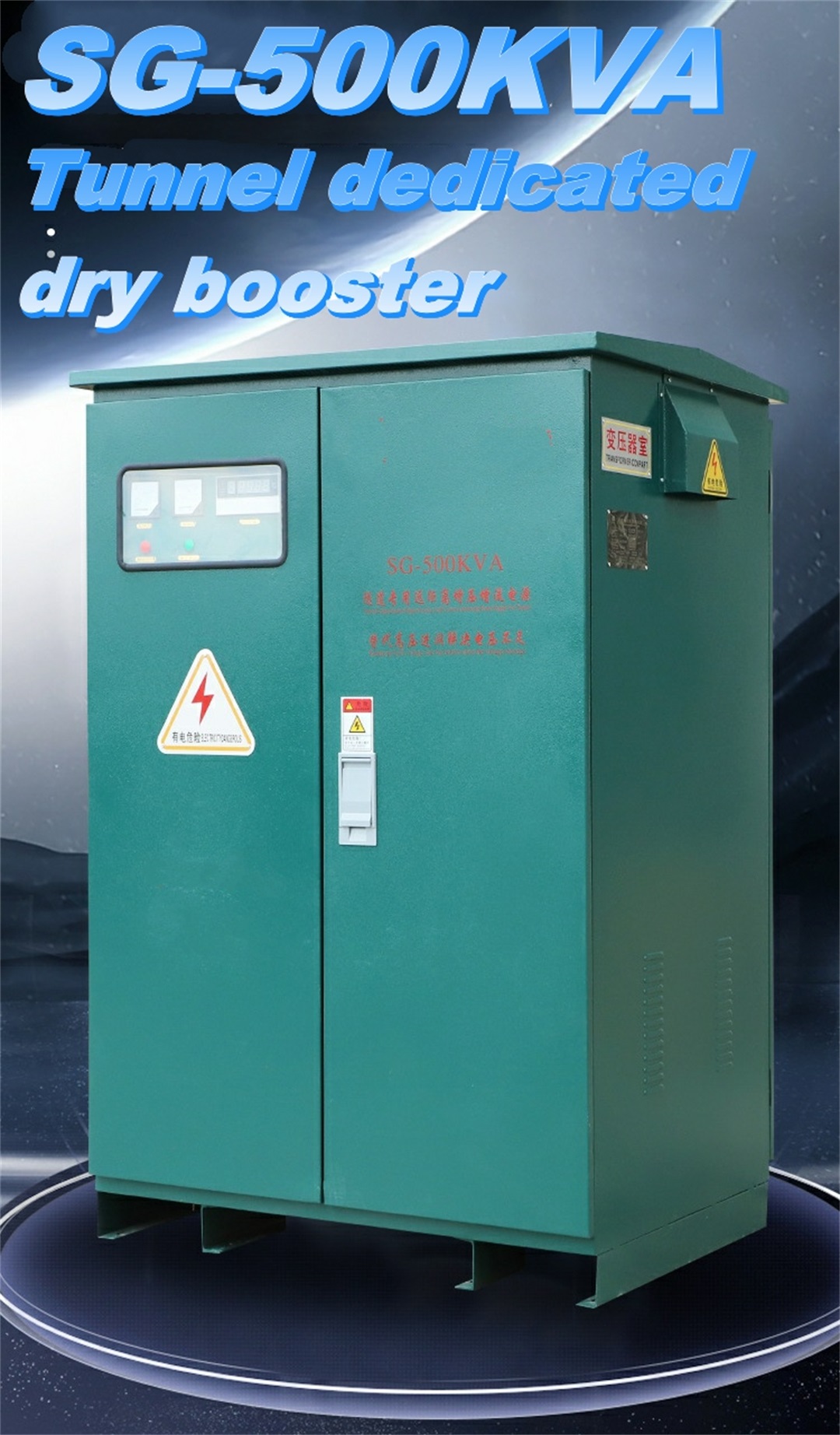

Product details

Products real shot

A corner of the production workshop

Product packaging

Product application case