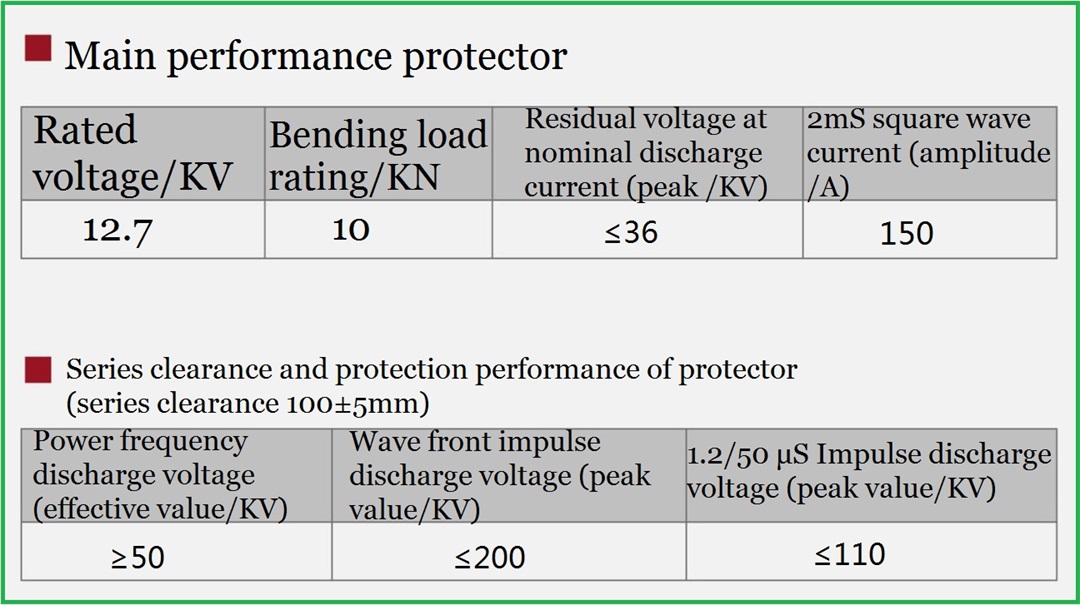

XHQ5 series 10KV 5KA Outdoor High voltage Overhead insulated line overvoltage protector

Product Description

Since the insulation level of 10KV lines is generally low, it is difficult to withstand the effects of direct lightning or induction lightning. If it is too high, it will also cause flashover, the insulation layer will be broken down, the continuous power frequency arc will burn here, and the wire will be blown in a very short time.

Line overvoltage protector refers to the equipment for protecting high-altitude lines. Direct lightning overvoltage or induced overvoltage caused by lightning strikes on overhead lines can easily lead to flashover or breakdown of insulators, resulting in power frequency freewheeling and high temperature arcs that instantly fuse the wires. In order to prevent this accident, it is necessary to install a line overvoltage protector on the overhead line. Its function is to guide the lightning current to the protector when the overhead line is struck by lightning, and cut off the power frequency continuous current to avoid flashover or breakdown of the insulator. Protect overhead lines from lightning strikes and disconnection accidents.

Product features

1. The excellent protection characteristics of the product, through the synergistic effect of the series gap formed between the drainage ring and the insulated wire and the current limiting element, can effectively cut off the power frequency freewheeling and avoid the disconnection accident of the insulated wire after a lightning strike;

2. The product Excellent protection characteristics, through the synergy between the series gap formed between the drainage ring and the insulated wire and the current limiting element, it can effectively cut off the power frequency freewheeling and avoid the disconnection accident of the insulated wire after lightning strike;

3. The special mechanical structure of the product (Including load-bearing frame and buffer layer), unique interface coupling technology and one-time molding process of silicone rubber jacket to ensure that the product can withstand large mechanical stress, reliable sealing, and explosion-proof;

4. The product is safe and reliable in operation and maintenance-free. Even if the protector is damaged due to abnormal conditions, the insulation coordination of the line will not be affected due to the isolation effect of the series gap, ensuring the safe operation of the power system.

Product use environment and installation

Use environment:

1. Ambient temperature: -40~50 degrees;

2. Altitude: 2000m and below (recommendation: use special plateau products above 2000m);

3. Power frequency: 58-62Hz, (60Hz system), 48 -52hz (50Hz system);

4. The air in the installation site should not contain chemical corrosive gases, steam, and explosive dust;

5. For long-term use under abnormal conditions, the protector needs to be specially ordered, and it should be specified in advance:

1) Temperature or the altitude exceeds the standard;

2) There are damp or corrosive gases and impurities in the use environment (water, salt field, chemical plant, etc.);

3) Strong ultraviolet radiation (plateau, strong sunshine and arid areas, etc.);

4) Extremely polluted areas (mine work surface, construction site working surface, etc.).

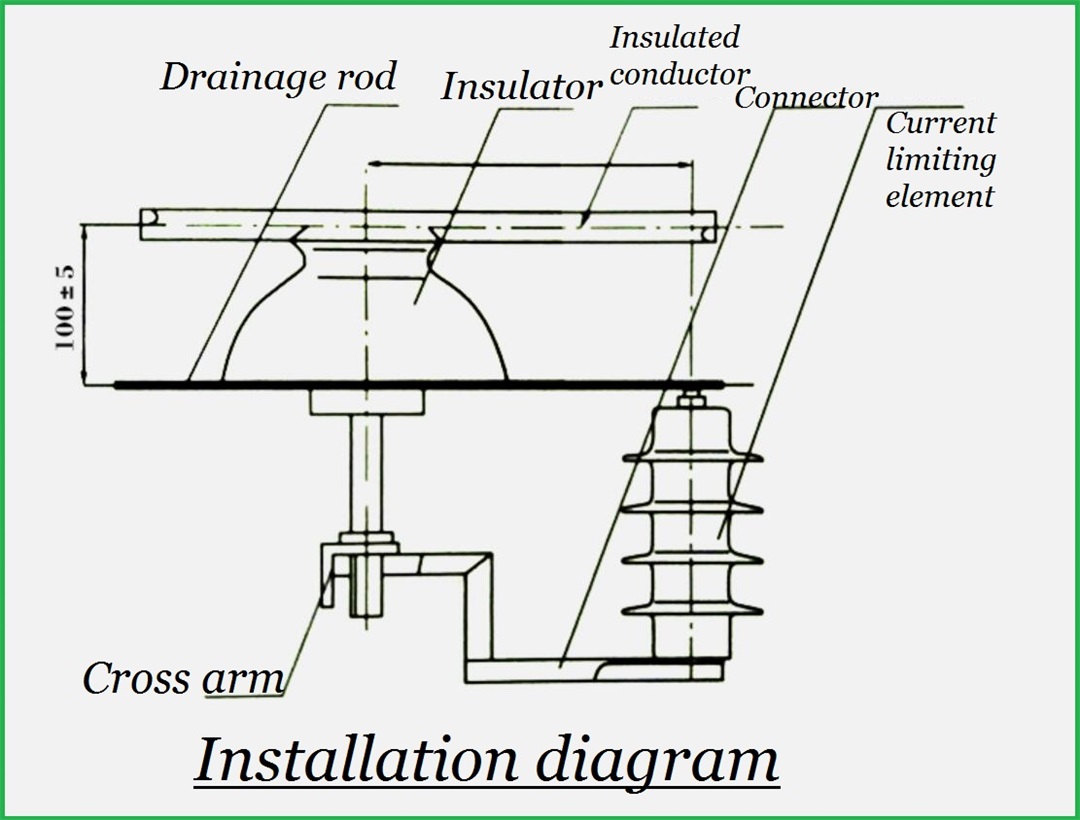

Product installation: install

in parallel with the insulator (PS-15); first unscrew the bolt on the upper end of the current limiting element, press the positioning nail on the pressure plate on the stainless steel drainage ring into the positioning hole on the upper end of the current limiting element, screw on the bolt and tighten it . Then fasten the restrictor element tightly on the coupling. When installing on a pole, unscrew the nut at the root of the insulator (PS-15), insert the round hole of the connector of the protector into the bolt at the root of the insulator, so that the drainage ring is evenly placed around the insulator (PS-15), so that the distance between them (If the gap between the stainless steel drain ring and the insulator is uneven, you can adjust the angle of the drain ring, the position of the connector, etc.), and finally tighten the nut at the root of the insulator and the bolt at the lower end of the current limiting element.

The overhead insulated wire must be placed in the groove on the top of the rod insulator (PS-15) (not in the side groove); the gap between the stainless steel drainage ring and the insulated wire (core) must be controlled within the range of 60-100mm Inside, the gap between the diversion ring and the insulator must be uniform and controlled within 25±5mm; for overhead insulated lines that do not strip the insulation layer, the arcs of the three-phase diversion ring should face the same direction and must be placed outside to avoid gaps between the diversion rings. If the interval is too small, it will affect the insulation coordination of overhead lines.

The grounding terminal adopts a special grounding wire, and the grounding resistance should be controlled below 30Ω, such as using galvanized steel bars, steel strands or flat steel with a cross-section of 50mm2; for hilly and other mountainous areas, the grounding resistance is large, and a special grounding grid needs to be constructed.

It is recommended to install one set on the top of each base pole in areas where lightning damage occurs frequently; in other areas, one set can be installed every two base poles.

Product details

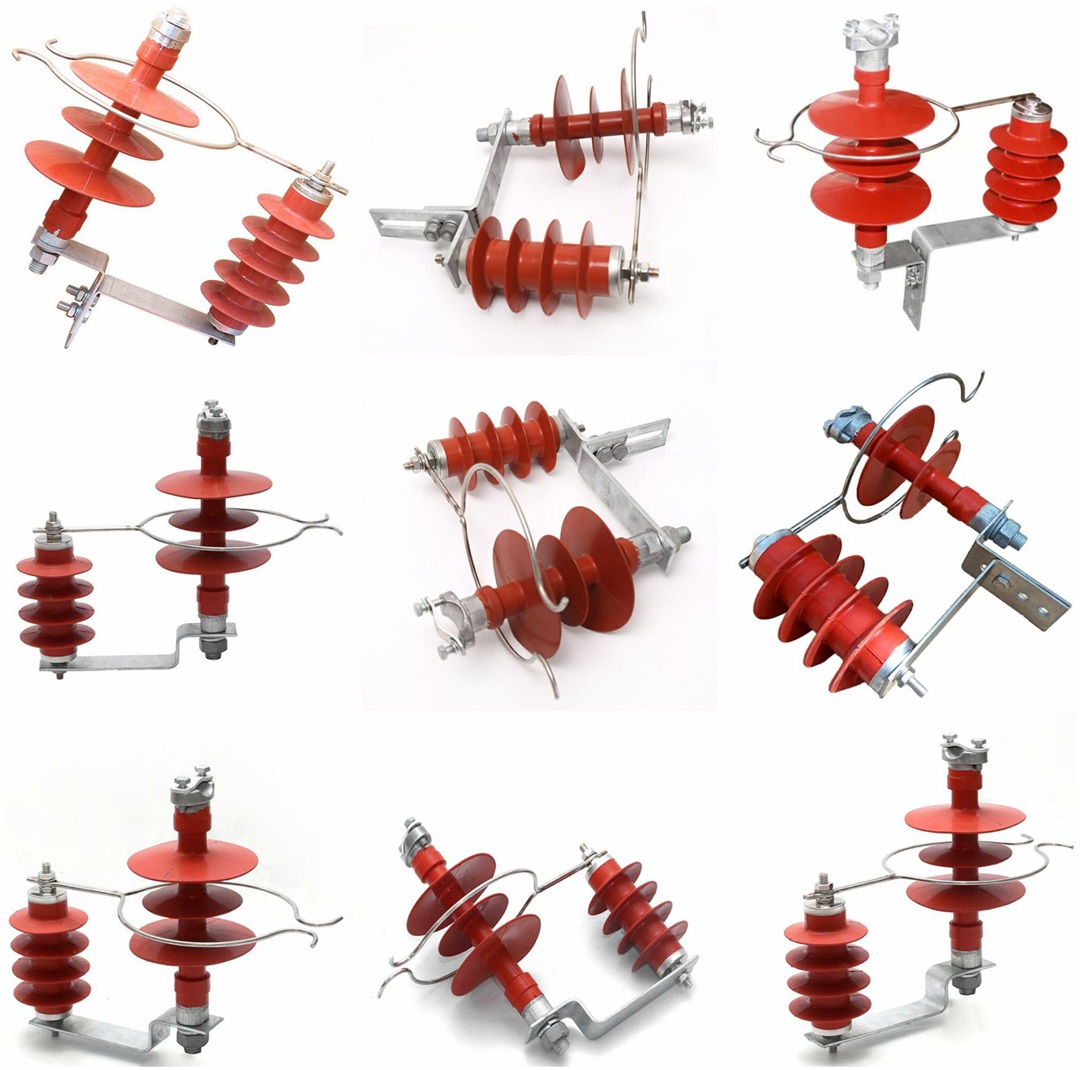

Products real shot

A corner of the production workshop

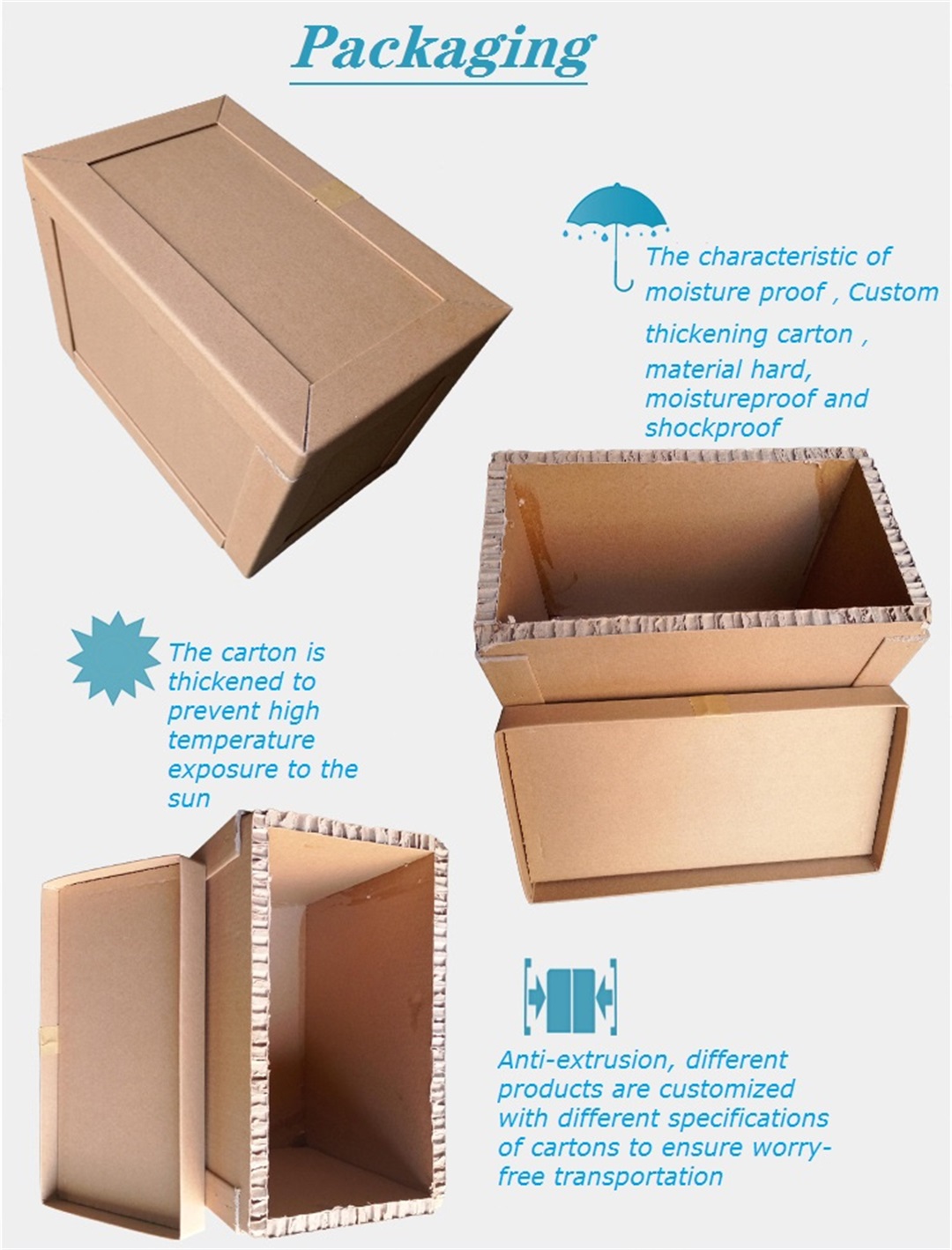

Product packaging

Product application case